Driven Precast Piles The side displacement of the dirt throughout driving is low can be fairly easily spliced or bolted. Light steel area or flynn piling pre-cast concrete coverings might be harmed or misshaped by tough driving. An enlarged base can be formed which can raise the loved one density of a granular starting stratum bring about a lot greater end bearing ability. Engineers will generally group a couple of piles together, and also leading them with a stack cap. A heap cap is a really thick cap of concrete that extends over a small group of stacks, as well as works as a base upon which a column can be constructed. In either case, power stack foundations do not contain a single energy heap however of a team of energy heaps that work as structural assistances and also geothermal heat exchangers. Because most of the stack's bearing ability is offered by shear stresses at its sidewalls, friction heaps are an excellent option when much deeper layers of more challenging product are present. The bulb of pressure is reduced by friction in between the heap's surface and also the earth, enabling the pile to spread its weight onto the bordering dirt. The driving of these stacks is smooth in the feeling that it doesnot create any adverse effect on the adjacent already drivenpile. The voids will certainly continue to be in the stacks if the concrete is not well-rammed and also the reinforcement is displaced from its original position. There is no wastefulness of material as the heap of called for length is just created. Hence, it additionally gets rid of the issues of extending or reducing of the heap. The amount of products needed for these piles is less. In situation of the Vibro bigger base heaps, a bigger footwear is offered which causes the increase of location of concrete block at the base. 2) When stacks are acting in a group.Again, neglecting completion bearing term for rubbing stack. Cover the surface area of the pre-cast stack with bitumen prior to driving. Negative skin friction or down drag is a phenomenon that occurs when a dirt layer surrounding a part of the heap shaft works out more than the stack. It is a down drag force exerted on a stack by the soil surrounding it. As a result of rotary action, the dirt is cut and comes under a pail. At the second phase, the pipe, and also button are increased to the required depth and also a corrugated steel covering is placed Inside the steel pipe. In the last stage, the pipe is gotten rid of and also concrete is put after any type of needed reinforcing has actually been set up. For an useful and cost-effective method of putting cast-in-situ concrete piles is called the Raymond stack system. Because 1984, Stack Buck has given the deep structures and also aquatic building and construction markets with information, pointers, tales, and also provider information. Stack Buck is released every two months and is dispersed worldwide.

Pile Driving Basics, Common Problems, And Options

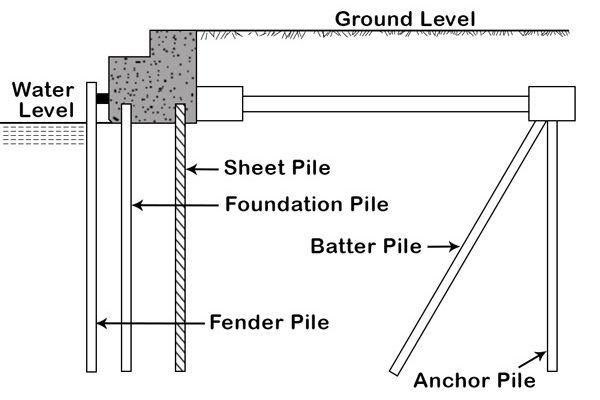

The pipeline is then gradually compressed instead of compacted. Fender stacks are generally made use of to protect coastal structures from ships or other floating things. Support stack is made use of to transfer compressive and tensile pressures to flexing moments on the ground securely.The Daily: Orlov Could Return to Caps; Red Wings' Doucet Piles Up ... - Detroit Hockey Now

The Daily: Orlov Could Return to Caps; Red Wings' Doucet Piles Up ....

Posted: Mon, 15 May 2023 14:13:46 GMT [source]

Hammer Padding

As pile structures are embeded in the soil, they are extra tolerant to erosion and comb. These approaches of maintaining wall surface building employ bored stacking strategies, typically CFA or rotating. They supply unique benefits where offered working space determines that basement excavation encounters be upright. The challenging facet of dealing with soil presents a variety of problems that can be expected. The task's threat reduction strategy can take into consideration most likely concerns to be encountered. Solutions can be included in contingency preparation-- preventing price overruns. The safety helmet is a short-term steel cap placed on top of the stack utilized to, as long as possible, protect the head throughout driving. A hammer cushion, normally made from synthetic materials, is placed in between the striker plate and also helmet. At the head of the heap is a best mini piling contractors north west shear lug, which fits machine-driven, rotary hydraulic attachments.- They can be found in a selection of forms, including square, octagonal, and circular.Suction stacks are utilized undersea to safeguard floating platforms.These heaps are used in special applications such as in marine atmospheres as well as within dirt areas revealed to seasonal changes.They bear upon frictional resistance in between their external surface as well as the soil in get in touch with.

What are the three sorts of heaps?

- Driven piles.Bored piles.Driven and also cast-in-situ piles.Aggregate heaps.Stacks are pushed into the ground to act as a constant support for structures built on top of them. Heaps transfer the tons from frameworks to hard strata, rocks, or dirt with high bearing capacity. The piles support the framework by staying well placed in the soil. A pile is a long cylinder comprised of strong product normally concrete.